National technology policy and current related fire protection

- Categories:Case Show

- Author:

- Origin:

- Time of issue:2021-01-29 14:37

- Views:

(Summary description)This specification is mainly for the planning, design and construction of the computer room and rack related parts of the data center of Dongtu cabinet. In the overall construction strategy of "meeting the present and adapting to the future", the equipment cabinets of Dongtu cabinets adhere to advanced, high reliability, high safety, sustainable development, easy management and maintenance, openness, and practicality in their design and construction. The principle of sex and comfort in order to finally realize the operation of a green data center with high energy efficiency and low energy consumption.

National technology policy and current related fire protection

(Summary description)This specification is mainly for the planning, design and construction of the computer room and rack related parts of the data center of Dongtu cabinet.

In the overall construction strategy of "meeting the present and adapting to the future", the equipment cabinets of Dongtu cabinets adhere to advanced, high reliability, high safety, sustainable development, easy management and maintenance, openness, and practicality in their design and construction. The principle of sex and comfort in order to finally realize the operation of a green data center with high energy efficiency and low energy consumption.

- Categories:Case Show

- Author:

- Origin:

- Time of issue:2021-01-29 14:37

- Views:

1. Technical parameters

1 General

This specification is mainly for the planning, design and construction of the computer room and rack related parts of the data center of Dongtu cabinet.

In the overall construction strategy of “meeting the present and adapting to the future”, the equipment cabinets of Dongtu cabinets adhere to advanced, high reliability, high safety, sustainable development, easy management and maintenance, openness, and practicality in their design and construction. The principle of sex and comfort in order to finally realize the operation of a green data center with high energy efficiency and low energy consumption.

The design and installation of equipment cabinets comply with national technical policies and current relevant standards and regulations on fire protection, safety, earthquake resistance, environmental protection and energy conservation.

2 Executive standard

East Figure cabinet executive standards: in line with ANSI/EIA RS-310-D, IEC297-2, DIN41491; PART1, DIN41494; PART7, GB/T3047.2-92 standards; compatible with ETSI standards.

3 Environmental requirements

1) Working temperature: -5℃~40℃.

2) Storage temperature: -20℃~+55℃.

3) Working relative humidity: no more than 85% (at +30℃).

4) Storage relative humidity: ≤90%~96% (40℃±2℃).

5) Atmospheric pressure: 76~106kpa.

6) Vertical gradient: ≤5%.

7) Transportation: the normal transportation of vehicles such as trains, ships, cars and airplanes. The packaged product can be adapted to normal transportation conditions without any damage to the appearance and performance of the equipment.

4 Basic technical specifications for equipment cabinets

4.1 Appearance and structure

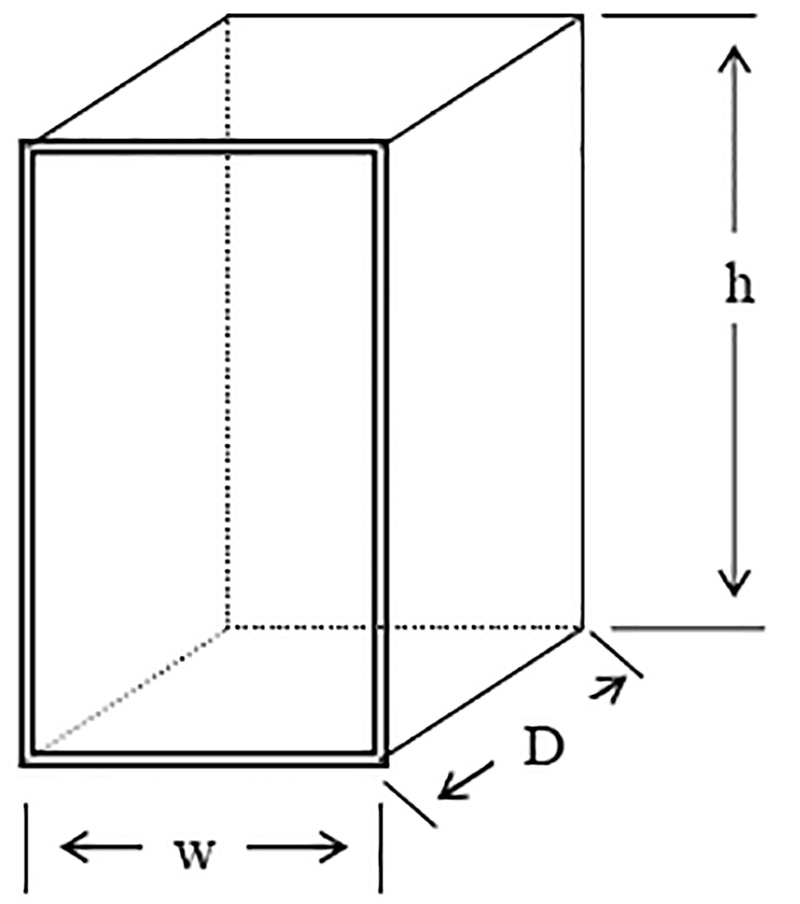

The dimensions of the cabinet are defined as follows:

Cabinet width (W) optional: 600/800

Depth (D) optional: 600/800/900/1000/1100/1200

Height (H) optional: 2000 (42U) / 2200 (47U) / 2400 (56U), etc.

1) The cabinet adopts external door opening method. The front and back convection super transparent hexagonal mesh doors. The meshes are arranged in a honeycomb and high-density order. The diameter of the inscribed circle of the hexagonal mesh is 7.9mm, the hole spacing is 1.1mm, and the mesh is ventilated. The rate is as high as 78%. The mesh area and the door panel are flat and not deformed. After the door panel is assembled, there are no undesirable phenomena such as inclination, depression, protrusion or partial distortion.

2) The front and rear doors of the cabinet are externally sealed with a package frame. The door panel adopts a one-time molding process structure. The front door of the cabinet is designed to open with a single leaf, and the opening rate of the door panel is over 75%. The back door of the cabinet is designed to open in the middle symmetrically, and the opening rate of the door panel reaches more than 70%. The front and back doors are equipped with high-class and elegant locks, which are beautiful and generous, and the door locks feel comfortable to open. The contact position between the door and the frame is coated with styrofoam damping strips. After the front and rear doors are installed, there is no tilt, depression, bulge or partial crooked or twisted phenomenon.

3) The door panel is a detachable structure. The opening and closing of the door is flexible, reliable, easy to assemble and disassemble. It can be easily disassembled and can be opened and closed by left or right. The opening angle of the door is not less than 130°, and the gap is less than 3mm.

4) The cabinet frame is welded with nine-fold profiles formed by one-time roll forming, and the structure is stable and reliable. The profile is made of SPCC1.5mm high-quality cold-rolled steel plate, with 25mm magic holes distributed on the profile, which provides universal installation for mounting beams, square hole bars and other accessories.

5) The cabinet is designed with up and down wiring, and the top plate of the cabinet has 4 wire inlet holes. It can fully satisfy the separation of strong and weak current and signal lines to ensure the safety of signals and cables from interference. When the cabinet does not require cabling or uses only part of the cabling holes, the unused cabling holes can be closed with a cabling hole cover. There is a large square hole in the middle of the top plate, which can be installed with Dongtu's patented fan module for heat dissipation, and it can also be used for wiring. When not in use, it can be closed with a small cover for flexible adjustment.

6) 6 connecting square hole bars (a cabinet with a depth of 1000 or more) are installed in the cabinet for installing equipment and fixing laminates. The square hole strip can be moved forward and backward, and the installation height and position of the shelf can also be adjusted, which can adapt to the installation requirements of servers and other equipment.

7) Installation beam: It is made of 1.5mm high-quality cold-rolled steel plate. The cabinet is installed with 3 pairs of installation beams, which strengthen in the depth direction to ensure the stability of the overall structure while fixing the square hole strips and some other vertical ones. annex.

8) Square hole strip: It is made of 2.0mm high-quality cold-rolled steel plate. In order to ensure the stability of the cabinet, the square hole strip adopts a five-point (600 wide cabinet) fixed connection to the upper and lower frames and installation beams. The square hole strip has no sharp edges and sharp corners to avoid cutting hands and scratching the equipment when installing the equipment. The installation dimensions of the square hole bar and the installation beam can be flexibly adjusted according to customer needs. The internal dimension structure of the cabinet such as the hole distance shall meet the requirements of GB/T 3047.2. The screen printing of the square hole strips increases the U mark from bottom to top, and the width of the installation surface of the square hole strip is ≥30mm. After the device is installed, the screen printing "U" number mark on the square hole strip will not be covered by the device; the inside of the square hole strip Has a larger installation space.

9) The installation position of the square hole strip: the front hole strip is 100mm away from the front door, and the rear hole strip is 200mm away from the back door. In order to meet the needs of different rental customers, the installation position of the square hole strip should be adjustable.

10) Fully sealed panels are used from the front door of the cabinet to the side of the square hole strip to ensure that the cold air entering from the front of the cabinet can be enclosed in the cabinet and will not be emitted from the panel and side panels of the cabinet.

11) Laminate: It is made of 1.2mm high-quality cold-rolled steel plate by multiple bending, which is firm and stable. The load-bearing capacity of the standard laminate is ≥60kg and the load-bearing capacity of the reinforced laminate is ≥100kg. The laminate is easy to install and disassemble, and its installation height and front and rear positions can be adjusted. The fixing method of the layer board can be fixed according to the needs, and the fixing method such as screw fixing compatible with clamping part fixing or elastic plug pin can be selected. After the laminate is installed, make sure that it does not protrude from the front of the front pillar, so that there is no gap between the sealed panels for installation.

12) L guide rail: made of 2.0 high-quality cold-rolled steel sheets, after the installation of the L guide rail, the distance between the bottom edges of the L guide rail on the same horizontal plane is ≦352mm; the bottom side of a single L guide rail exceeds the effective length of the inner side of the square hole for carrying equipment ≧50mm, to prevent some narrow equipment from being unable to be put on the shelf. The standard L guide rail bears 50KG, and the reinforced model bears 100KG; there are at least 6 bends at the bending part to avoid the expansion of the L guide by more than 90 degrees after the server is put on the shelf, which will affect the shelf of the next server; the design length of the L guide is about 400~700mm, can be adjusted according to the depth of the cabinet and the needs of users. The side and square hole bars are fixed with screws. The screw fastening operation surface is on the inside of the cabinet. After the angle iron is fixed, its corners can completely avoid affecting the rack installation of the server; The distance between both ends of the L guide rail and the front scale side of the square hole bar should be at least 20mm to avoid blind plates and cable organizers from being unable to install.

13) Fake panel: Used to close the space where no equipment is installed, to prevent the waste of air-conditioning, and to maximize the heat dissipation of the equipment. The dummy panel specifications are 1U/2U/4U high, and the dummy panel is made of lightweight 0.8mm thick cold-rolled steel plate. The dummy panel is designed for quick-opening installation and is fixed without tools.

14) The cabinet side door panel is divided into two-section side door panel and cabinet side door panel. The two-section side door panel is a quick-open structure, which is easy to disassemble and assemble. It can also be locked. The cabinet side door panel is used to close the cabinet to prevent the cabinet. The airflow flows horizontally in the room, and the installation of the side door does not affect the combination of cabinets, nor does it affect the overall width of the cabinets.

15) The rear of the cabinet can be equipped with cable troughs, cable tie plates, fish-bone cable troughs, etc. for cable management and wiring, so that the cabinets are reasonably wired and neat and beautiful.

16) Grounding bar: The cabinet is equipped with a vertical grounding bar, and the cross-sectional area of the grounding copper bar is 25*3mm. The installation position of the cabinet ground bar is convenient for the equipment to be grounded. It is installed on the right rear facing the cabinet. The cabinet ground point is above the cabinet. The cabinet and the grounding bus bar are connected. The cabinet grounding point above the cabinet is connected to the ground. The cabinet ground bar is at least 3 Fixed point; each grounding copper bar in the cabinet is pre-opened to multiple wiring holes.

17) The cabinet body has a firm structure, all fittings are standard, can be used interchangeably, fasteners are not loose, and exposed and operating parts have no sharp edges and burrs.

18) The cabinets can be installed side by side, and are equipped with parallel connection pieces. The two cabinets are combined at 6 o'clock, which is stable and reliable. After the cabinets are combined, there is no obvious light-transmitting gap between the cabinets; the combined cabinets are reasonably arranged for easy disassembly and do not affect the installation of other accessories and the sealing of the hot and cold aisles.

19) Surface quality: the surface of the frame is treated with degreasing, nano-ceramics, pure water cleaning, electrostatic spraying, etc., no paint removal, acid and alkali resistance, solvent resistance, corrosion resistance, fingerprint resistance, not affected by hand sweat, 100% adhesion, Shock resistant. The surface treatment adopts high-hardness powder electrostatic spraying and high-temperature baking paint treatment process, the surface appearance is smooth, uniform color, no exposed bottom, no flow, no blistering, no cracks, no orange peel, no burrs and corrosion of metal parts, anti-static; The welding seam is neat and uniform, and there are no defects such as cracks, undercuts, gaps, burn-through, etc. The surface of the welding seam has no defects such as slag inclusion, pores, welding bumps, pits, etc., after welding, the surface roughness should meet the relevant industry standards. The surface spraying of external parts must meet the national non-toxic and harmless spraying standards and meet environmental protection requirements.

20) The full set of colors can choose RAL9004 or other colors. The surface coating color of the cabinet meets the requirements in GB/T 3181-2008, professional high-hardness powder, to ensure that it meets the anti-static and BS6497 international standards, and meets the European ROSH standards;

21) The screw holes of the connecting posts in the cabinet for fixing the shelf and the server are reasonably and evenly spaced.

22) The static load of the normal cabinet can reach 1000kg, and the static load of the reinforced cabinet can reach 1600kg.

4.2 Internal function configuration of equipment cabinet

1) 220V AC power distribution unit (PDU) is optional inside the cabinet for power distribution of the servers in the cabinet. The power distribution unit is installed vertically without affecting equipment installation

4.3 Protective earthing and working earthing device

The back of the cabinet near the column or at the bottom of the rack can be optionally equipped with copper bars for the protective grounding of communication equipment. The copper bars must be made of red copper, and the surface is nickel-plated to enhance conductivity. The grounding copper bars are connected to the grounding of the equipment and the protective grounding wire.排连接。 Row connection. The cross-sectional area of the grounding copper bar should be 75mm2. The grounding copper bar is pre-opened with several round holes with a diameter of 6mm to borrow copper lugs. All parts of the cabinet are prefabricated with grounding devices. All parts can be connected into one through grounding wires. As a whole, the cabinet parts are connected to each other to form an equipotential;

5 Cabinet seismic strength

According to the requirements of the "Specifications for Seismic Performance Testing of Telecommunications Equipment" (YD 5083-2005), the comprehensive cabinet shall not be detached, dropped, and separated under the action of full load and earthquake intensity of 7, 8, and 9. The following requirements should be met:

1) After the 7-intensity earthquake resistance assessment, the structure of the equipment under test must not be deformed or damaged;

2) After the 8 intensity earthquake resistance assessment, the tested equipment should ensure its structural integrity, the main structure is allowed to be slightly deformed, and the connecting part is slightly damaged during transportation, but any welding part must not be damaged;

3) After the 9-intensity earthquake resistance assessment, the main structure of the tested equipment is allowed to partially deform and damage, but the equipment must not fall.

6 Basic structure and function of cold aisle closed system

6.1 Appearance and structure

1) The top cover of the cold aisle adopts a flat top structure, which is 320mm higher than the top of the cabinet. The height can also be increased or decreased according to customer requirements, or a flat top structure of the cabinet.

2) There are three types of skylights at the top of the cold aisle: fixed skylights, movable skylights, and functional skylights. According to the type of skylight used, after the movable skylight is opened, ensure that the clear height of the cold aisle is greater than 2 meters or more, and does not affect the daily maintenance work and the safety of maintenance personnel.

3) The cold aisle closed system should be a unit modular design. Install the top of the front of the cabinet. Each unit can be installed independently and can be connected to adjacent units. The frame needs to be connected with the horizontal support of the cabinet with special connection holes to increase the overall stability; in addition to strengthening the channel itself, it also plays a role in facilitating expansion.

4) A movable door is set between the column head and the column tail to form a sealed space, allowing the cold air flow to enter the equipment effectively.

5) The movable door frame on both sides of the cold aisle adopts cold-rolled steel frame, and the transparent observation window adopts 5mm tempered glass inside. The whole is flat and beautiful, and the color is consistent with the cabinet.

6) The movable door of the cold aisle is designed to be normally closed, and an automatic door closing device is installed. The doors are all equipped with buffer and airtight devices to provide better protection. The push-pull handle can be installed in both directions according to customer needs, and the tightness of the door and the rack is required.

7) The pre-set port of the cold aisle airtight system is integrated with the fire control of the engine room, and the movable skylight should be automatically opened according to the fire signal of different forms of the engine room to eliminate the danger in the aisle.

8) All unit components of the cold aisle airtight system adopt unique good wear resistance, corrosion resistance, fine processing, integral stamping forming, high reliable contact, unit opening life tests are more than 5,000 times, and there should be no looseness in safety and durability requirements. Ensure the air tightness of the air output.

9) A single cold aisle has independent environmental detection to achieve real-time detection of the temperature and humidity values in the channel, and at the same time to meet the setting of the return difference value to prevent control oscillation when the current temperature and humidity value reaches the adjacent control value, and control the generated oscillation value Within the allowable range, and send out an alarm signal.

10) Irregular aisle treatment. When the cabinets on both sides of the cold aisle are not in one-to-one correspondence, install a partition wall opposite the relevant cabinet (at 1200mm or adjust according to the specific location of the site). The material of the partition wall is all steel plate or a combination of steel plate and glass. The wall keel is integrally fixed with other adjacent keels of the cold aisle. The whole is firm and beautiful.

11) Treatment of cold aisle columns. When there are columns in the middle of the cabinets on both sides of the cold aisle, if the columns are recessed into the cabinet, install and partition walls on both sides of the vertical columns (to the front of the cabinet); if the columns protrude from the front of the cabinet , Install a partition wall between the vertical column and the cabinet. The material of the partition wall is full steel plate or a combination of steel plate and glass, and the keel of the partition wall should be integrally fixed with other adjacent keels of the cold aisle. The overall requirement is firm and beautiful.

12) All metal parts of the cold aisle closed system can be grounded to achieve overall grounding,

13) Cameras in the aisle can be installed at the beginning and end of the cold aisle.

14) The cold aisle airtight system is designed with a reasonable environmental detection position, 5~10 channels are not less than 1 collection point, 11~15 channels are not less than 2 collection points, and 16~20 channels are not less than 3 Collection point.

15) The overall sealing performance of the top cover and door of the cold aisle reaches IP30, which meets the fire protection regulations.

16) Material: All selected materials must be fire-retardant materials.

6.2 Cold aisle closed system function

The cold aisle closed system must be an active monitoring system plan to prevent abnormal events caused by equipment operating failures or equipment working environment and human factors. When the internal environment of the passage exceeds the preset threshold, the movable sunroof of the closed system should be automatically opened, and the sound and light alarm should be turned on at the same time and the on-site staff will be notified through the central control unit to deal with; when there is an emergency situation such as a fire alarm inside the passage, It should be able to be controlled by the fire control center signal and open automatically to ensure that a large enough area is used for the rapid injection of fire fighting gas. It is required to turn on the sound and light alarm at the same time and notify the on-site staff through the central control unit to deal with it.

The closed system satisfies the airflow containment function requirements, and completely isolates the cold and hot airflow. The passage doors at the first and last ends should be designed to be normally closed. There should be no obvious gaps in closed components such as skylights and skeletons. The skeleton must have the function of arranging and hiding cables. All cables laid in the closed system shall not be exposed.

1) The environmental management host is applied to the monitoring, linkage and power supply of all monitoring equipment in the control channel, and it is required to realize the free switching function of multiple alarm logics and processing mechanisms. At the same time, it is required to collect a variety of data such as smoke, temperature and humidity, and environmental information collection in the channel, as well as link skylights, sound and light alarms and other functions.

2) Intelligent equipment with independent working power supply unit, through the magnetic suction power supply to achieve the skylight fixation. It can be linked with the control host or fire control signal at the same time to realize the function of automatically opening the top cover. Can quickly respond to microenvironment monitoring.

3) The open sunroof has an independent monitoring and management function, which can collect signals from the central control unit and feed it back to the monitoring center to monitor the status of the sunroof in real time. At the same time, the sunroof can also be opened by a manual forced stop device.

4) All skylights are designed to be quickly installed or disassembled without tools to meet daily maintenance and replacement.

5) The cold aisle closed system can be designed for cold light source lighting according to customer needs. The cold light source should be 200 lumens or more to meet the equipment shelf and daily maintenance work in the aisle.

7. Technical features

flexibility:

The cold aisle is a unit modular design, the corresponding two cabinets occupy 1 unit, each unit can be installed independently, and can be connected with adjacent units

Intelligence:

The hot and cold aisles are equipped with 3 safety setting functions (temperature, humidity, smoke detection) and 1 central control (mandatory switch), which can automatically open and close the cold aisle according to the temperature

safety:

This system does not affect fire safety. When the temperature rises to a certain level during a fire, the system will open the top of the cold aisle that was originally closed to allow the fire fighting gas in the machine room to enter the aisle

structure

Both sides of the cold aisle machine room are manually pushed and pulled, and there shall be no door frames, guide rails and other facilities that hinder the entry and exit of equipment transportation vehicles on the floor of the cold aisle entrance door.

The sliding door frame on both sides of the cold aisle is made of cold-rolled steel frame, and the inside is 5mm ~ 10mm coated tempered glass, and the glass area is not 70% of the small door. The whole is flat and beautiful, and the color is consistent with the cabinet.

The joint action with the fire-fighting system of the engine room is adopted to solve the fire-fighting requirements in the cold aisle. The top of the cold aisle has the function of automatically opening the top cover of the fire linkage. The working mode: in the normal state, the top cover of the flap is attracted by the energized magnet, and the flap surface is parallel to the aisle to achieve a sealing effect. Before the system starts, the electromagnet of the flap top cover is powered off and tripped, and the flap top cover opens quickly due to the action of gravity, ensuring that the fire extinguishing gas enters the closed cold aisle space from the flap top cover after the fire fighting system is started.

According to the situation of the existing computer room, each cold aisle closed system is designed according to the number of cabinets.

The entire structure meets the requirements of the national fire protection code.

size:

The cold-aisle fire-fighting skylight frame is made of cold-rolled steel plates above 1.5mm ~ 2.0mm, and the frame sealing method is sealed by a special sealing machine. The interior is coated with tempered glass above 5mm. In order to ensure the light transmission in the channel, the glass area is not less than that of the skylight. 80%, the size of the top cover is 600MM*1200MM, the top cover frame adopts professional magnetic lock, the lock plate adopts blue zinc electroplating treatment, anti-residual magnetism design, and the lock core is double insulated.

Sealing grade:

The cold aisle requires the sealing performance to reach IP30~IP33 and meet the fire protection regulations.

other

When designing and manufacturing the cold aisle, the power column head cabinet is enclosed in the cold aisle.

In the cold aisle closed system, all materials such as cabinets, doors, top covers, connectors, and fire linkage devices are supplied as a whole.

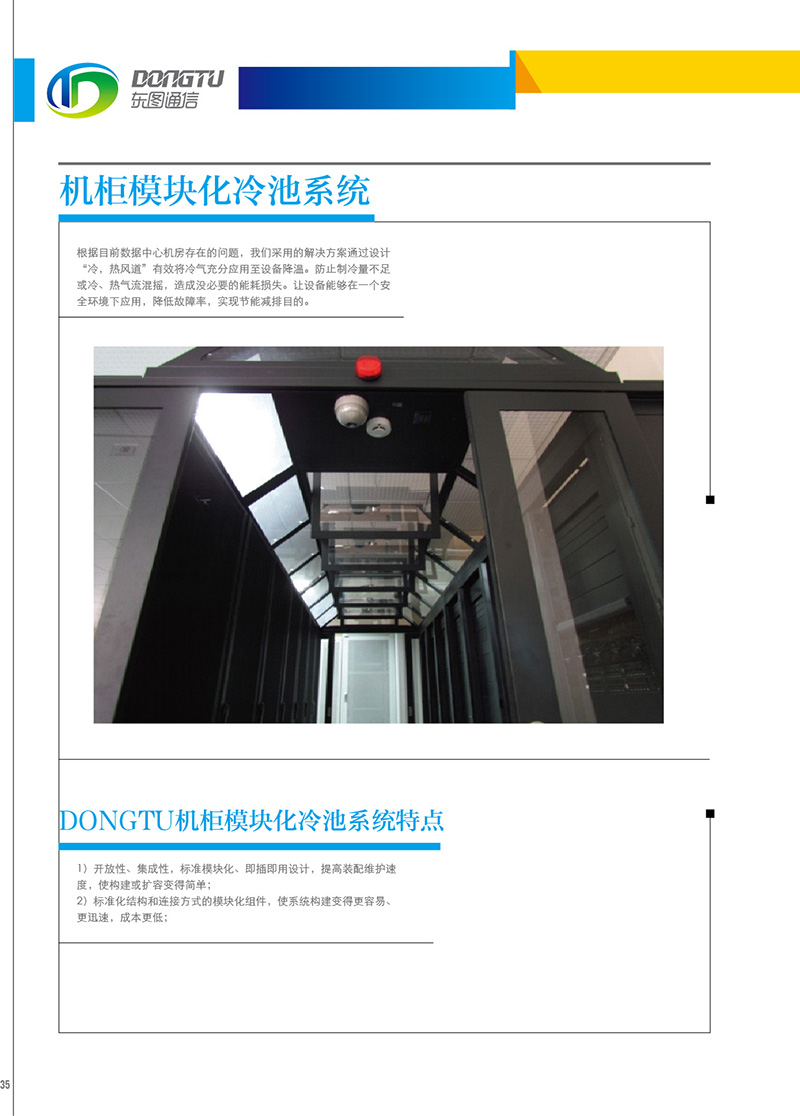

2. Company color page introduction

3, technical solutions

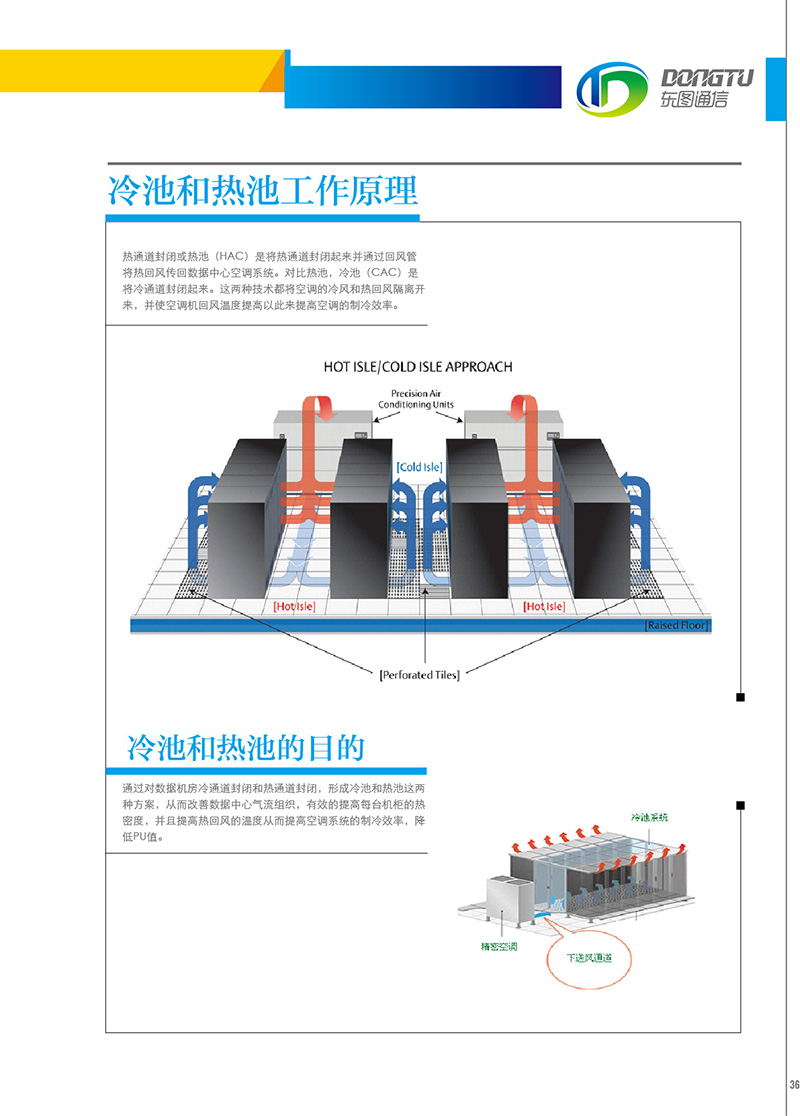

1. Cold pool layout

1) Every two rows of front doors form a cold pool to the front door

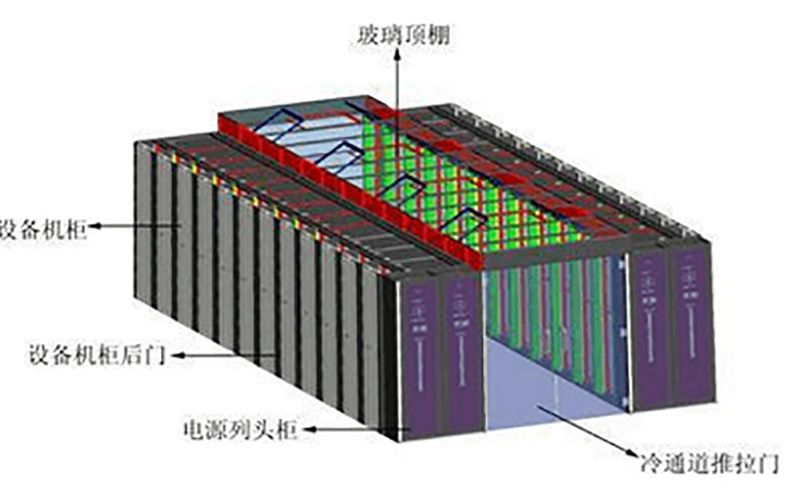

2) There is a cold pool top closed between the cabinet and the cabinet, and the two ends of the cabinet are closed by cold pool doors (see Figure 1)

Figure 1 Effect picture of cold pool

3) Two options are suggested for cold aisle ceiling: a) Steel structure frame + tempered glass (film), double-door structure, opening to the outside of the aisle, its advantages: good safety and scrub resistance b) Steel structure frame + laminated glass, Double-door structure, open to the outside of the channel, its advantages: good safety and scrub resistance

4) The fixed ceiling of the cold pool is removable for easy cleaning and scrubbing.

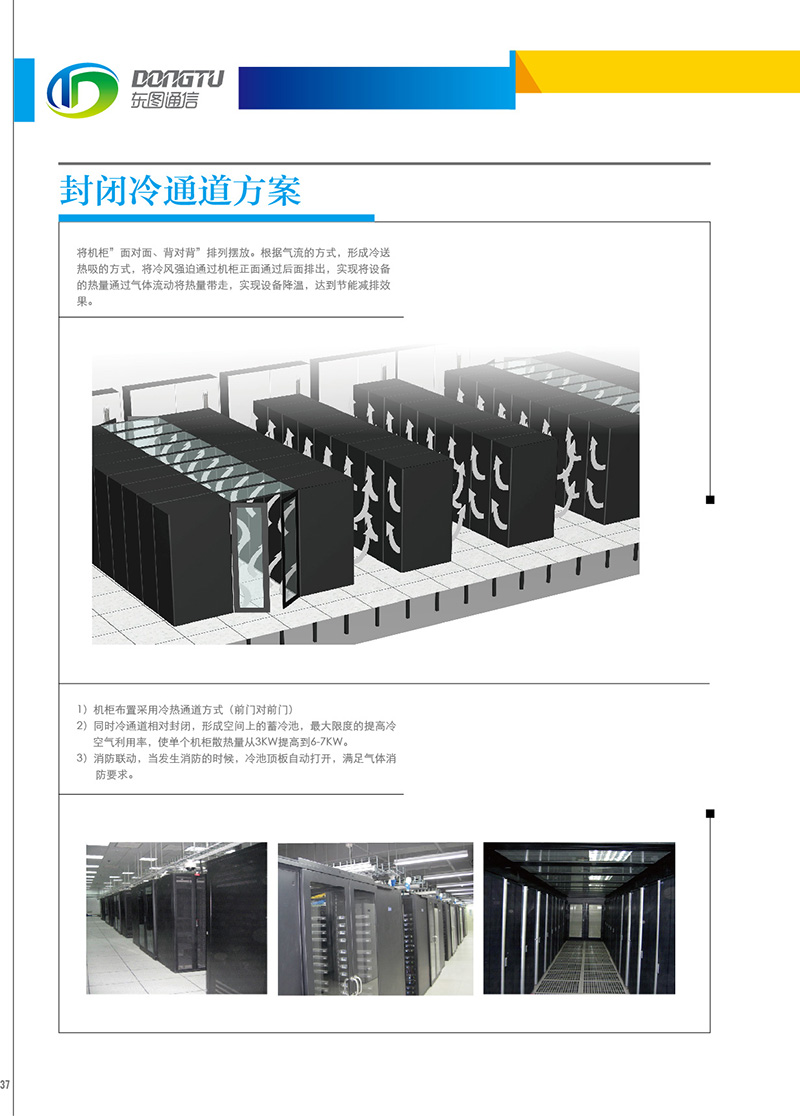

2. Fire linkage

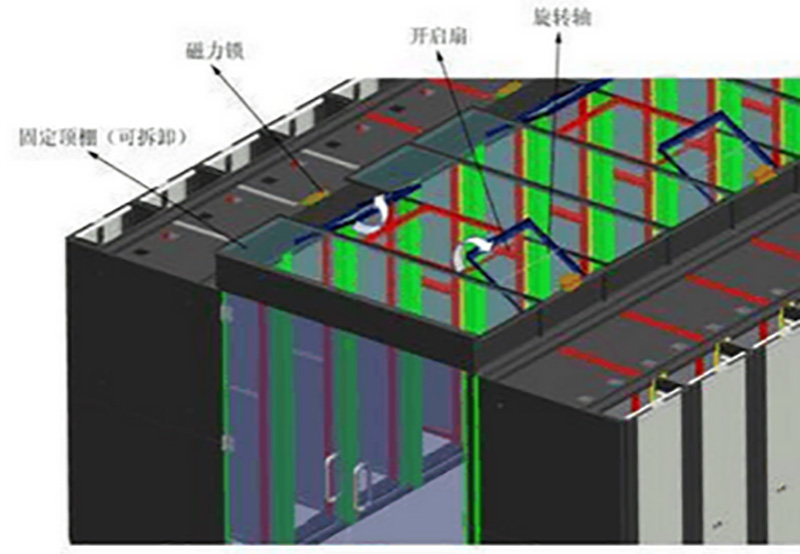

1) A movable ceiling and a fixed ceiling are set on the top of the cold pool, and a set of movable ceilings are set for every 2 fixed ceilings, and 2 open fans are set on the cold pool top of each movable ceiling (see Figure 2)

Figure 2 The ceiling of the cold pool

2) After the opening fan is turned on, the distance from the bottom edge to the ground is 1850mm, the depth of the opening fan is 550mm, and the height of 1800mm is slightly higher than the height of a person. When opened, the safety is good. 3) An electromagnet is installed at the joint of the opening fan and the cabinet, a ) The fan is turned off in the normal state. When the machine room is powered off, the fan is turned on automatically, and it can be turned off manually when it is normal. Gravity opens automatically, and can be closed manually after normal.

Four, successful case pictures

1. Successful case of Dongguan Songshan Lake mobile computer room project:

The company undertook the Dongguan Songshan Lake mobile computer room project. For convenience, the computer room monitoring system is based on TCP/IP and adopts the B/S mode. Managers only need to browse through IE to realize the centralized or decentralized monitoring of multiple computer rooms and multiple monitoring quantities. .

The Songshan Lake mobile computer room project in Guan City was constructed and debugged by our company. The final stage is mainly for the power equipment of the computer room and the changes in ambient temperature and humidity.

In August 2016, the Songshan Lake mobile computer room project in Dongguan City was successfully completed. The cost of this project is over tens of thousands. From the perspective of engineering quantity and cost, it is another successful case of our company.

The following is the product picture of this project:

The following picture is a successful case picture of the company's project:

-

Tel

-

Message

-

Top

Guangzhou Dongtu Communication Equipment Co., Ltd.

Address: Room 521, Qiaoxing Building, No. 33 Xingnan Avenue, Nancun Town, Panyu District, Guangzhou

Tel: 4008070138

E-mail: gzdongtu@163.com

COPYRIGHT © 2020 Guangzhou Dongtu Communication Equipment Co., Ltd. ALL RIGHTS RESERVED. 粤ICP备2020115305号

By: 300.cn